dodge jaw crusher pdf

Capacities and performance characteristics of jaw crushers

Although jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood. This lack of understanding makes selection of the proper machine difficult. Hersam (1923) proposed a method for calculating capacities using a Dodge-type jaw crusher.

Jaw Crusher Capacities, Blake and Single-Toggle Or

Reduction of data from one type or size of jaw crusher into the equivalent performance of another crusher has been accomplished by ratios of all of the various equation factors involved. The individual u Fig. 3-Dodge-type jaw crusher showing relative swing jaw motion at feed and discharge ends.

“Computer Aided Design of Jaw crusher” nitrkl.ac

1.1 Single toggle blake type jaw crusher 3 1.2 Double toggle blake type jaw crusher 4 1.3 Dodge Type Jaw crusher 5 1.4 Schematic Diagram of a jaw crusher 8 2.1 Equivalent four bar mechanism diagram 13 2.2 Graph: Crank angle v/s angle made by moving jaw with Y axis 15

CHAPTER 1 1.0 INTRODUCTION mechanical.uonbi.ac.ke

Dodge jaw crusher The movable jaw is pivoted at the bottom. Maximum amplitude of motion is obtained at the top of the crushing plates. Dodge type crushers are not used for heavy duty and are commonly found in laboratories. Fig 2.8: Dodge type jaw crusher . Small scale mechanized stone crusher 2010/2011

Jaw Crushers JW Series

Available as static jaw crushers for a custom fit for your application or available in pre-engineered modular and portable options for easy transport and installation. MODULAR PORTABLE STATIC Modular Model Main Components Motor Size Capacity (MTPH) Shipping Configuration MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW

Dodge Crusher Mineral Processing & Metallurgy

Feb 23, 2016 Dodge Crusher. A sectional view of the Dodge jaw crusher here below. The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut. Dodge-type crusher parts: (1) Frame, 12) Main bearing cop, (3) Oil well cover, (4) Oil well cover spring, (5) Swing jaw shaft box, (6

Mini Jaw Crusher Sepor

The Mini-Jaw Crusher is a single toggle type of miniature laboratory jaw crusher. The major operating components are illustrated (less drive) in the cross section, above. The movable jaw is attached to the drive via the eccentric shaft. The rotation of the eccentric shaft causes the movable jaw to move towards the stationary jaw in an

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Jaw Crushers mekaglobal

Jaw Crushers MJ 90, MJ 110 and MJ 130 Technical Specification Jaw Crushers reduce large size rocks or ore by placing the rock into compression. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. There are also primary and secondary types of jaw crushers.

International Journal of Advance Engineering and Research

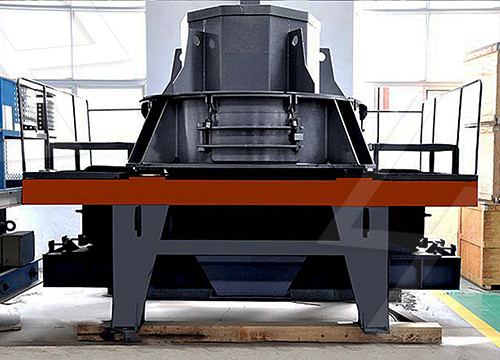

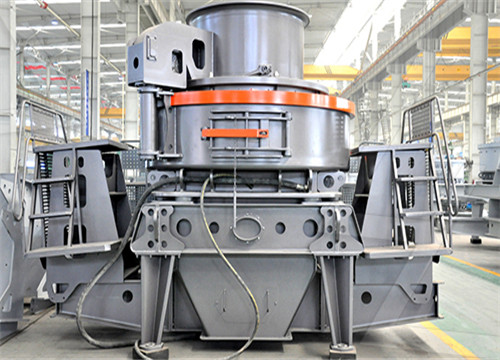

Figure 1 Jaw Crusher Structure III. DIFFERENT TYPES OF JAW CRUSHER Jaw crusher can be divided into two according to the amplitude of motion of the moving face. The different types of Jaw Crushers are: 1) Blake Type Jaw Crusher, 2) Dodge Type Jaw Crusher Figure-2 Blake Type Jaw Crusher Figure-3 Dodge Type Jaw Crusher IV.

Capacities and performance characteristics of jaw crushers

Although jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood. This lack of understanding makes selection of the proper machine difficult. Hersam (1923) proposed a method for calculating capacities using a Dodge-type jaw crusher.

Jaw Crusher Capacities, Blake and Single-Toggle Or

Reduction of data from one type or size of jaw crusher into the equivalent performance of another crusher has been accomplished by ratios of all of the various equation factors involved. The individual u Fig. 3-Dodge-type jaw crusher showing relative swing jaw motion at feed and discharge ends.

“Computer Aided Design of Jaw crusher” nitrkl.ac

1.1 Single toggle blake type jaw crusher 3 1.2 Double toggle blake type jaw crusher 4 1.3 Dodge Type Jaw crusher 5 1.4 Schematic Diagram of a jaw crusher 8 2.1 Equivalent four bar mechanism diagram 13 2.2 Graph: Crank angle v/s angle made by moving jaw with Y axis 15

Jaw Crushers JW Series

Available as static jaw crushers for a custom fit for your application or available in pre-engineered modular and portable options for easy transport and installation. MODULAR PORTABLE STATIC Modular Model Main Components Motor Size Capacity (MTPH) Shipping Configuration MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW

Dodge Crusher Mineral Processing & Metallurgy

Feb 23, 2016 Dodge Crusher. A sectional view of the Dodge jaw crusher here below. The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut. Dodge-type crusher parts: (1) Frame, 12) Main bearing cop, (3) Oil well cover, (4) Oil well cover spring, (5) Swing jaw shaft box, (6

principle operation jaw crusher pdf

Jaw Crusher Working Principle. Metallurgical ContentJAW CRUSHERSDouble Toggle Jaw CrushersSingle toggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the single toggle type of jaw crusher is shown below In one respect the working principle and application of this

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Jaw Crushers mekaglobal

Jaw Crushers MJ 90, MJ 110 and MJ 130 Technical Specification Jaw Crushers reduce large size rocks or ore by placing the rock into compression. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. There are also primary and secondary types of jaw crushers.

PE SERIS JAW CRUSHER

Dsmac DMP series Mobile Jaw Crusher plant DMP series Mobile jaw crusher plant puts crushing and screening process on wheels. By combining feeding, crushing and screening equipment together with belt conveyor, This plant is widely used in mine, building material, highway, rail way and hydropower industries, etc.

(PDF) " Design and Finite Element Analysis of Swing Jaw

The different types of Jaw Crushers are: 1) Blake Type Jaw Crusher, 2) Dodge Type Jaw Crusher Figure-2 Blake Type Jaw Crusher Figure-3 Dodge Type Jaw Crusher IV. INTRODUCTION TO FINITE ELEMENT METHOD FEA has

HEAVY -DUTY CRUSHERS -Milwaukee

to design jaw crushers for maximum strength, rugged endurance, and least cost of ownership in the industry. Frames are stress relieved before machining to ensure uniform heavy-duty strength. • Heavy-duty, oversized heat-treated shafts forged of special alloy to

C Series jaw crushers

group, has installed over 10 000 jaw crushers since the 1920s. Today the C Series is indisputably the world’s favourite jaw crusher. Where cost-efficient primary reduc-tion of hard, abrasive materials is concerned, C Series crushers represent the highest tech-nical and manufacturing knowledge. All C Series jaw crushers are based on a

Abstract— Keywords IJSER

1.3.2 Dodge Type Jaw Crusher . The movable jaw is pivoted at the bottom and connected to an eccentric shaft. The universal crushers are pivoted in the middle so that the jaw can swing at the top and the bottom as well. Maximum amplitude of motion is obtained at the top of .

International Journal of Advance Engineering and Research

Figure 1 Jaw Crusher Structure III. DIFFERENT TYPES OF JAW CRUSHER Jaw crusher can be divided into two according to the amplitude of motion of the moving face. The different types of Jaw Crushers are: 1) Blake Type Jaw Crusher, 2) Dodge Type Jaw Crusher Figure-2 Blake Type Jaw Crusher Figure-3 Dodge Type Jaw Crusher IV.

Capacities and performance characteristics of jaw crushers

Although jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood. This lack of understanding makes selection of the proper machine difficult. Hersam (1923) proposed a method for calculating capacities using a Dodge-type jaw crusher.

Jaw Crusher Capacities, Blake and Single-Toggle Or

Reduction of data from one type or size of jaw crusher into the equivalent performance of another crusher has been accomplished by ratios of all of the various equation factors involved. The individual u Fig. 3-Dodge-type jaw crusher showing relative swing jaw motion at feed and discharge ends.

“Computer Aided Design of Jaw crusher” nitrkl.ac

1.1 Single toggle blake type jaw crusher 3 1.2 Double toggle blake type jaw crusher 4 1.3 Dodge Type Jaw crusher 5 1.4 Schematic Diagram of a jaw crusher 8 2.1 Equivalent four bar mechanism diagram 13 2.2 Graph: Crank angle v/s angle made by moving jaw with Y axis 15

Jaw Crushers JW Series

Available as static jaw crushers for a custom fit for your application or available in pre-engineered modular and portable options for easy transport and installation. MODULAR PORTABLE STATIC Modular Model Main Components Motor Size Capacity (MTPH) Shipping Configuration MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW

Dodge Crusher Mineral Processing & Metallurgy

Feb 23, 2016 Dodge Crusher. A sectional view of the Dodge jaw crusher here below. The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut. Dodge-type crusher parts: (1) Frame, 12) Main bearing cop, (3) Oil well cover, (4) Oil well cover spring, (5) Swing jaw shaft box, (6

principle operation jaw crusher pdf

Jaw Crusher Working Principle. Metallurgical ContentJAW CRUSHERSDouble Toggle Jaw CrushersSingle toggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the single toggle type of jaw crusher is shown below In one respect the working principle and application of this

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Jaw Crushers mekaglobal

Jaw Crushers MJ 90, MJ 110 and MJ 130 Technical Specification Jaw Crushers reduce large size rocks or ore by placing the rock into compression. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. There are also primary and secondary types of jaw crushers.

PE SERIS JAW CRUSHER

Dsmac DMP series Mobile Jaw Crusher plant DMP series Mobile jaw crusher plant puts crushing and screening process on wheels. By combining feeding, crushing and screening equipment together with belt conveyor, This plant is widely used in mine, building material, highway, rail way and hydropower industries, etc.

(PDF) " Design and Finite Element Analysis of Swing Jaw

The different types of Jaw Crushers are: 1) Blake Type Jaw Crusher, 2) Dodge Type Jaw Crusher Figure-2 Blake Type Jaw Crusher Figure-3 Dodge Type Jaw Crusher IV. INTRODUCTION TO FINITE ELEMENT METHOD FEA has

HEAVY -DUTY CRUSHERS -Milwaukee

to design jaw crushers for maximum strength, rugged endurance, and least cost of ownership in the industry. Frames are stress relieved before machining to ensure uniform heavy-duty strength. • Heavy-duty, oversized heat-treated shafts forged of special alloy to

C Series jaw crushers

group, has installed over 10 000 jaw crushers since the 1920s. Today the C Series is indisputably the world’s favourite jaw crusher. Where cost-efficient primary reduc-tion of hard, abrasive materials is concerned, C Series crushers represent the highest tech-nical and manufacturing knowledge. All C Series jaw crushers are based on a

Abstract— Keywords IJSER

1.3.2 Dodge Type Jaw Crusher . The movable jaw is pivoted at the bottom and connected to an eccentric shaft. The universal crushers are pivoted in the middle so that the jaw can swing at the top and the bottom as well. Maximum amplitude of motion is obtained at the top of .

- теория принципа конусной дробилки

- валковая дробилка обо

- дробылки из китая дробилка

- б у 100 т ч дробилка

- дистрибьютор дробилка индонезийская дробильная установка

- сделать дробилку пластика схема чертеж

- молоткова дробилка разрез

- Хобби Фрезерный Станок Отзывы

- каменная дробилка ремесло

- Современная каменная дробильная установка

- Каменная дробильная машина и ударная дробилка

- грохот гил 42

- о челюсти дробилка принцип работы

- Старинная ручная ручная дробилка

- Оптимизация схемы флотации

- Производитель шаровой мельницы в Бангалоре

- камень линию вибрационный питатель

- отчет по проекту железорудной дробилки

- определение токарного станок

- дробильная установка назад

- таиланд переработке золота завод

- ремонт дробилки сгруппированный ремонт дробилки в шри-ланке

- сколько стоит стержневая мельница

- песок дл приготовлени машины в индии

- Время Кальцита Мельницы