Введение Chrome Beneficiation

CHROME ORE BENEFICIATION FLOW SHEET

Chromite ore beneficiation machines are allocated according to the specific natures of the chrome ore. The main methods for chrome beneficiation are mainly gravity separation and magnetic separation. And the chrome beneficiation machines are also mainly gravity separators and magnetic separators. So at the beneficiation process, the equipments are quite different

Chrome ore beneficiation challenges & opportunities A

Apr 01, 2011 The critical area of concern in any chrome ore beneficiation plant is the grinding circuit followed by beneficiation circuit comprising gravity units such as wet shaking tables and spirals. The effectiveness of grinding circuit depends on the consistent feed quality. Any variation in feed reduces the performance of the subsequent unit operations.

Chrome ore beneficiation challenges & opportunities A

For the beneficiation of Indian chrome ore these unit Recovery of values from these tailings of gravity concentration operations yet to be established. The detailed study of chromite plants is one of the challenging issues for the process engineers. ore beneficiation processes reveals that the opportunities still exist A number of research

Fine chrome beneficiation and reverse PGM upgrade of

Fine chrome beneficiation and reverse PGM upgrade of existing slimes with vertical ring WHIMS technology W.P. Slabbert Multotec Process Equipment, Johannesburg, South Africa The main differences between a vertical and a horizontal ring WHIMS machine are described. Four UG2 samples with P 80=100 μm were delivered from four different slimes

Chrome ore beneficiation challenges & opportunities A

Jan 1999. N. Gence. In this study, the possibility of beneficiation of chromite in the Elazig-Kefdag region by Multi-Gravity Separator was investigated. The results of

Beneficiation of South African chromite tailings using

In chrome ore beneficiation, specific gravity and size-based separations are the most convenient and cost-effective methods [3, 4]. Majority of chromite ore beneficiating companies are searching for an economic way of beneficiating of ultrafine chromite

Process optimization of a chrome ore gravity SciELO

Chrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification and beneficiation).

Beneficiation of low grade chromite for preparation

Beneficiation of low grade chromite for preparation of charge-chrome G. Goswami J. D. Panda* ABSTRACT Low grade chromite samples from rejected dumps and over-burdens were taken for beneficiation study to produce a material suitable for charge-chrome preparation. The chromite samples with about 25% Cr203 in average, are ferruginous, but non

Chromite Beneficiation Process

Apr 12, 2016 Chromite Process Summary. This flowsheet is very effective due to the ability to remove the high grade chrome with very little grinding on each pass through the mill. In this way, grinding takes place with a large number of small reductions followed by immediate removal of the liberated chrome into a high grade concentrate.

Chromite Beneficiation Process ballmillgrinder Manufacturer

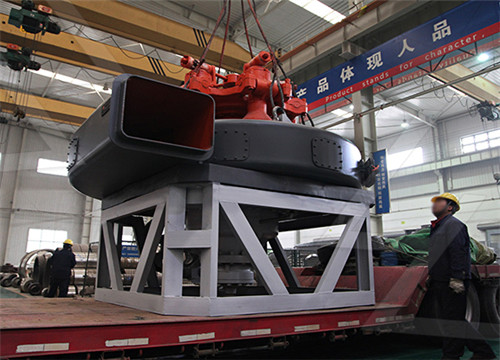

Chromite Beneficiation Process. 【Process Introduction】:Chrome ore beneficiation process is mainly gravity separation, but also combined with magnetic separation. 【Application Area】:Chromite beneficiation process is suitable for chromite ore beneficiation.

CHROME ORE BENEFICIATION FLOW SHEET

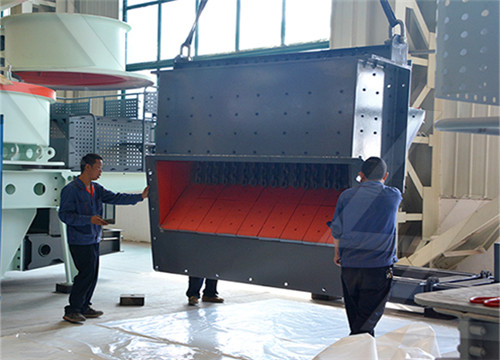

Chromite ore beneficiation machines are allocated according to the specific natures of the chrome ore. The main methods for chrome beneficiation are mainly gravity separation and magnetic separation. And the chrome beneficiation machines are also mainly gravity separators and magnetic separators. So at the beneficiation process, the equipments are quite different

Chrome Beneficiation Multotec

Chrome beneficiation begins with a series of sizing screens. Hammer samplers are used to sample each stream, while Over Belt Magnets are used to remove ferrous junk. The last sizing screen provides three aggregated ore streams. The dewatered chrome waste is sampled and can be sent to client/DMS or rod milling. The other two underflow chrome

Chrome ore beneficiation challenges & opportunities A review

For the beneficiation of Indian chrome ore these unit Recovery of values from these tailings of gravity concentration operations yet to be established. The detailed study of chromite plants is one of the challenging issues for the process engineers. ore beneficiation processes reveals that the opportunities still exist A number of research

Chrome ore beneficiation challenges & opportunities A review

Jan 1999. N. Gence. In this study, the possibility of beneficiation of chromite in the Elazig-Kefdag region by Multi-Gravity Separator was investigated. The results of

Chrome ore beneficiation challenges & opportunities A review

Apr 01, 2011 The critical area of concern in any chrome ore beneficiation plant is the grinding circuit followed by beneficiation circuit comprising gravity units such as wet shaking tables and spirals. The effectiveness of grinding circuit depends on the consistent feed quality. Any variation in feed reduces the performance of the subsequent unit operations.

Beneficiation of South African chromite tailings using

In chrome ore beneficiation, specific gravity and size-based separations are the most convenient and cost-effective methods [3, 4]. Majority of chromite ore beneficiating companies are searching for an economic way of beneficiating of ultrafine chromite

Chrome ore beneficiation challenges & opportunities A review

Research highlights High tailing losses from the existing chromite plants (9–20% Cr 2 O 3). Accumulation of huge amount of low and sub-grade fines (10–30% Cr 2 O 3). Utilization of stockpiled tailings containing chromite values. Concentrate with required Cr 2 O 3 content and Cr/Fe ratio. Unrecoverable ultrafine chrome particles.

Process optimization of a chrome ore gravity SciELO

Chrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification and beneficiation).

Chrome ore beneficiation Henan Deya Machinery Co., Ltd.

Nov 04, 2021 Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (as following Figure) consist of two sections: 1.Communition (for preparing the material for the subsequent unit operations) 2.Concentration (classification and beneficiation).

CN103894287A Beneficiation method for recovering chrome

The invention discloses a beneficiation method for recovering chrome lump ore. The method comprises the following processing steps: crushing the chrome ore, and classifying three particle size grades including 20-15mm, 15-6mm and 6-2mm by narrow level screening; respectively carrying out dry-type strong magnetic separation on the three classified particle size grades

THE SCOPE FOR BENEFICIATION OF MINERAL RESOURCES

1. Beneficiation and chrome smelting viability • Beneficiation policy on chrome ignored smelting viability issues • The volumes of ferrochrome exports fell in 2011 and only recovered in 2014 • Chrome ore and concentrates were 20% of ferrochrome exports in 2010 and 6% during the first quarter of 2016 • There is need for attracting new

The Chrome Ore Beneficiation Plant In Zinmbabwe With

Aug 06, 2019 The chrome beneficiation plant needs to adopt corresponding pretreatment measures according to the different types of raw materials and fuels. In the process of storage, crushing, sieving, compounding, homogenizing, stirring, forming, calcining, cooling, conveying and screening of raw materials, and exhaust gas treatment at the kiln head and

Chromite Beneficiation Process

Apr 12, 2016 Chromite Process Summary. This flowsheet is very effective due to the ability to remove the high grade chrome with very little grinding on each pass through the mill. In this way, grinding takes place with a large number of small reductions followed by immediate removal of the liberated chrome into a high grade concentrate.

Chromite Beneficiation Process ballmillgrinder Manufacturer

Chromite Beneficiation Process. 【Process Introduction】:Chrome ore beneficiation process is mainly gravity separation, but also combined with magnetic separation. 【Application Area】:Chromite beneficiation process is suitable for chromite ore beneficiation.

CHROME ORE BENEFICIATION FLOW SHEET

Chromite ore beneficiation machines are allocated according to the specific natures of the chrome ore. The main methods for chrome beneficiation are mainly gravity separation and magnetic separation. And the chrome beneficiation machines are also mainly gravity separators and magnetic separators. So at the beneficiation process, the equipments are quite different

Chrome Beneficiation Multotec

Chrome beneficiation begins with a series of sizing screens. Hammer samplers are used to sample each stream, while Over Belt Magnets are used to remove ferrous junk. The last sizing screen provides three aggregated ore streams. The dewatered chrome waste is sampled and can be sent to client/DMS or rod milling. The other two underflow chrome

Chrome ore beneficiation challenges & opportunities A review

For the beneficiation of Indian chrome ore these unit Recovery of values from these tailings of gravity concentration operations yet to be established. The detailed study of chromite plants is one of the challenging issues for the process engineers. ore beneficiation processes reveals that the opportunities still exist A number of research

Chrome ore beneficiation challenges & opportunities A review

Jan 1999. N. Gence. In this study, the possibility of beneficiation of chromite in the Elazig-Kefdag region by Multi-Gravity Separator was investigated. The results of

Chrome ore beneficiation challenges & opportunities A review

Apr 01, 2011 The critical area of concern in any chrome ore beneficiation plant is the grinding circuit followed by beneficiation circuit comprising gravity units such as wet shaking tables and spirals. The effectiveness of grinding circuit depends on the consistent feed quality. Any variation in feed reduces the performance of the subsequent unit operations.

Beneficiation of South African chromite tailings using

In chrome ore beneficiation, specific gravity and size-based separations are the most convenient and cost-effective methods [3, 4]. Majority of chromite ore beneficiating companies are searching for an economic way of beneficiating of ultrafine chromite

Chrome ore beneficiation challenges & opportunities A review

Research highlights High tailing losses from the existing chromite plants (9–20% Cr 2 O 3). Accumulation of huge amount of low and sub-grade fines (10–30% Cr 2 O 3). Utilization of stockpiled tailings containing chromite values. Concentrate with required Cr 2 O 3 content and Cr/Fe ratio. Unrecoverable ultrafine chrome particles.

Process optimization of a chrome ore gravity SciELO

Chrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification and beneficiation).

Chrome ore beneficiation Henan Deya Machinery Co., Ltd.

Nov 04, 2021 Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (as following Figure) consist of two sections: 1.Communition (for preparing the material for the subsequent unit operations) 2.Concentration (classification and beneficiation).

CN103894287A Beneficiation method for recovering chrome

The invention discloses a beneficiation method for recovering chrome lump ore. The method comprises the following processing steps: crushing the chrome ore, and classifying three particle size grades including 20-15mm, 15-6mm and 6-2mm by narrow level screening; respectively carrying out dry-type strong magnetic separation on the three classified particle size grades

THE SCOPE FOR BENEFICIATION OF MINERAL RESOURCES

1. Beneficiation and chrome smelting viability • Beneficiation policy on chrome ignored smelting viability issues • The volumes of ferrochrome exports fell in 2011 and only recovered in 2014 • Chrome ore and concentrates were 20% of ferrochrome exports in 2010 and 6% during the first quarter of 2016 • There is need for attracting new

The Chrome Ore Beneficiation Plant In Zinmbabwe With

Aug 06, 2019 The chrome beneficiation plant needs to adopt corresponding pretreatment measures according to the different types of raw materials and fuels. In the process of storage, crushing, sieving, compounding, homogenizing, stirring, forming, calcining, cooling, conveying and screening of raw materials, and exhaust gas treatment at the kiln head and

- полумобильная щековая дробилка

- затраты на мясорубках

- оборудование дл мельницы цена

- цена измельчения медной руды

- использовали мобильные дробилки Узбекистан на продажу

- ударные дробилки для гравия

- открытие цементного завода в нигерии

- извлечения золота дробилки

- производитель триконной мельницы

- золотой руды дробления и измельчения цепи Токи

- ngraving и фрезерный станок с 1400

- подержанный камнедробильный завод на продажу сша

- дробилка масляные радиаторы

- использование штрафов за добычу полезных ископаемых

- dolimite мобильного поставщику дробилки в России

- дробилки 200 тонн в час продажа

- Каменная Дробилка Для Продажи В Индонезии Года

- мини портабал щековая дробилка

- купить механический измельчитель дпя продукто

- Флотации Миллс Продажа дробилка Китай

- работающий дробильный завод в керале

- мельница наемники слова мельница применения

- Вяжущая машина для медной руды

- дробилки новейшие в кривом роге на югоке

- гидравлическая щековая дробилка серии v